Client Challenge

1. Extremely high material purity – No bubbles, high transparency, zero impurities, crystal-like clarity.

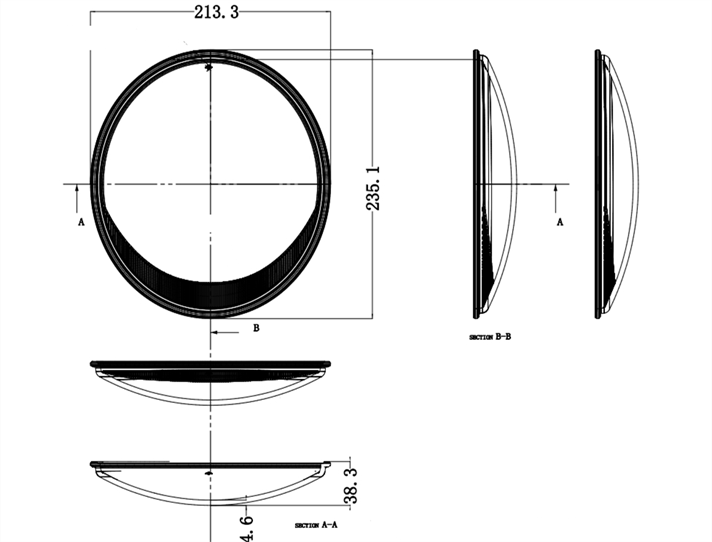

2. Strict mold requirements – Nearly flawless samples required mirror-finish molds with ultra-high precision.

3. Complex process control – Machine speed, output, and mold temperature had to be perfectly balanced.

Our solution

1. Exclusive material formula – Ensured crystal-grade optical clarity.

2. High-precision mold fabrication – Enhanced material & finishing, achieving full mirror-polish surfaces.

3. Fully automated production – Maintained balanced raw material usage, speed, and mold temperature for stability.

Final Rezult

1, Achieved crystal-clear transparency, bubble-free & impurity-free, meeting optical standards for sports car headlamps.

2, Mirror-polished precision molds delivered near-zero defect forming with consistent mass production quality.

3, Client received headlamp glass matching premium automotive standards, enabling smooth mass production and strengthening strategic trust in Easter Glass.

◆ ≥ 97% Transparency ◆ Ra ≤ 0.05 μm Mold Surface Accuracy ◆ 99.9% Pass Rate