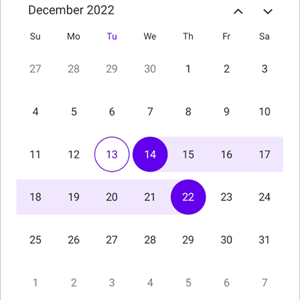

Provide Delivery Date

We provide a confirmed delivery date to ensure clear production scheduling and transparent communication.

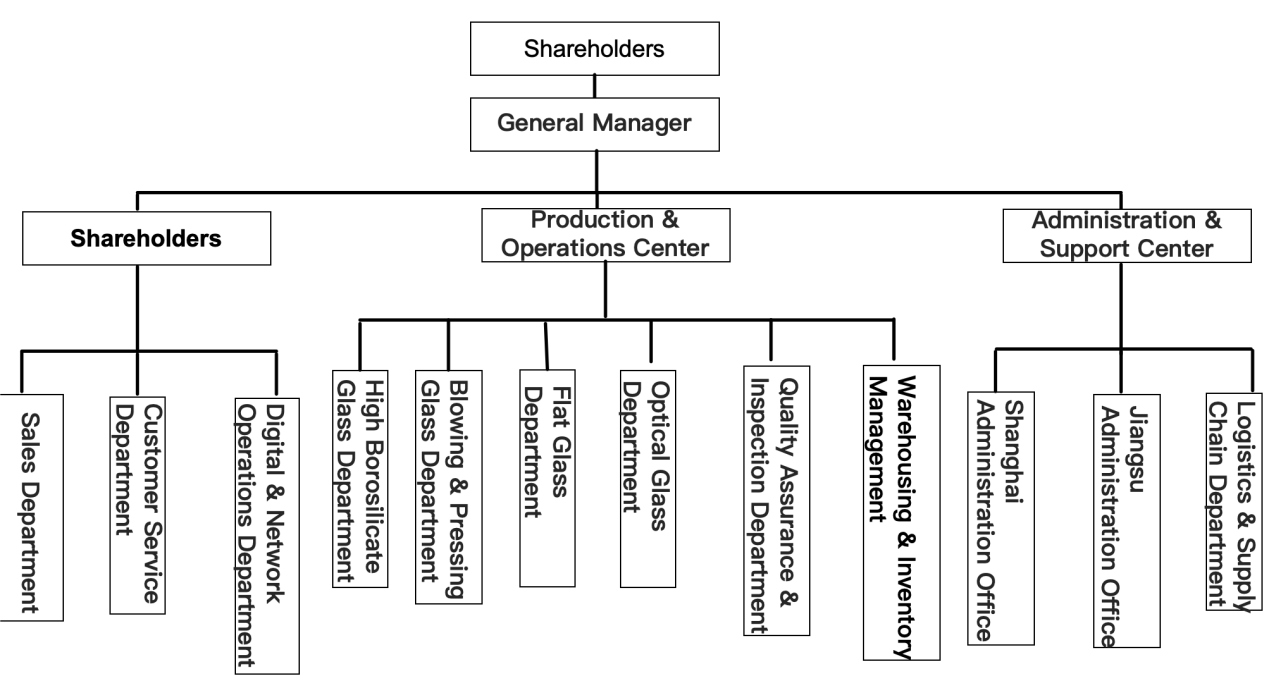

Easterglass originated in Shanghai, beginning in 2005 as a trading company specializing in customized glass products, including lighting, crafts, tableware, and packaging. In 2012, after taking on a project for Switch Lighting (USA), we realized that as a middleman we could not fully meet the customer’s urgent needs in production progress, technical upgrades, and quality control. To better serve clients, we established our own factory while keeping the Shanghai office as a trade hub.

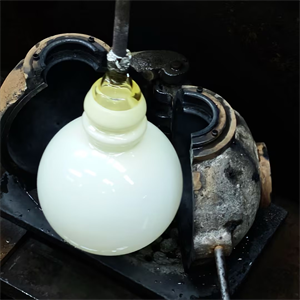

By 2017, we repositioned ourselves to focus solely on the commercial lighting sector, adopting a “Shanghai office for orders, factory for production” model, which won long-term recognition and trust. Over 20 years, our factory has grown from a 200 m² workshop to a 6,000 m² standard plant, creating an efficient trade–manufacture integrated model. We specialize in blown glass, precision-pressed glass, high borosilicate processing, optical and flat glass, all custom-made to client drawings.

As a direct manufacturer, we save customers 15–35% in costs by cutting out intermediaries. Beyond competitive pricing, our unique 12-step transparent service system ensures smooth communication, full production visibility, and worry-free sourcing. Leveraging Shanghai’s international advantage, all service staff are certified in advanced English and product knowledge, ensuring accuracy and avoiding costly misunderstandings.

At Easterglass, we don’t just sell products—we help clients grow.

“For custom glass, no need to search far and wide—Easterglass has it all.”

Years ago, when I came to Shanghai, my only intention was to find a stable job. But once I entered the glass industry, I quickly witnessed a harsh reality: many companies cared only about profit. They neither understood nor respected their clients’ needs. Orders were accepted blindly, with no concern for whether they could be delivered on time or at the required quality. In the end, responsibilities were often shirked, and in the worst cases, factories shut down—leaving clients’ molds, drawings, and technical data lost forever. Customers suffered disappointment and financial loss time after time. Projects failed repeatedly. Cooperation was no longer built on trust, but on confrontation.

This troubled me deeply. To me, the true purpose of a company is not to chase orders, but to take responsibility—to solve problems, and to help clients achieve their goals. If those goals cannot be realized, then profits and growth are nothing but empty shells. With this conviction, I chose to create my own path.

That is how Easterglass was born. The name comes from Easter, symbolizing rebirth, hope, and breakthrough. From day one, our vision has been to build a different kind of company—not just producing glass, but delivering professional expertise, fast and reliable execution, and consistent quality to transform our clients’ ideas from drawings into reality.

For more than two decades, we have refined our craft across every process: from fused-blown and precision-pressed glass to advanced borosilicate, optical, and tempered flat glass. Step by step, we have established full-category capabilities in customized glass for the commercial lighting industry. With more than 3,000 successful projects and deep insight into client needs, we have earned the trust of over 400 partners across Germany, France, the United States, and Western Europe. Along the way, Easterglass has grown into the trusted expert our clients turn to for solutions.

Today, Easterglass stands as the leading brand in commercial lighting glass customization. To us, every piece of glass is more than a product—it carries our clients’ vision, their market challenges, and their future opportunities. Helping them achieve all of this is not only our promise, but the very reason we exist.

Deepen our expertise in the industry

Tailored Production Experience

The processes of blowing and pressing

A transparent and well-defined service process

Production process line

At our company, we strive to be your trusted partner for all your needs. With a dedication to excellence and a proven history of success, we aim to provide you with the best possible experience. Here are some reasons why we believe you'll love working with us.

Our pricing strategy is built on rigorous cost management and innovative solution design, enabling customized production processes for each product model. This enhances cost-efficiency and supports our competitive pricing.

Over two decades, the company has maintained stability and sustained growth in pricing, quality, delivery times, packaging, team collaboration, and leadership. This ensures a robust foundation for business operations.

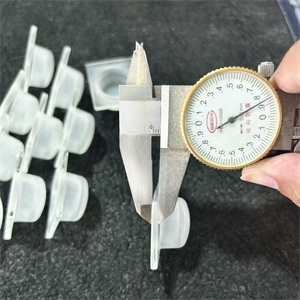

Highly skilled teams craft products meticulously, prioritizing customer quality requirements. Each item comes with a comprehensive "production history record," ensuring consistent high standards through stringent processes and a robust traceability system.

Our business team members are proficient in English (CET-6 or higher), enabling accurate interpretation of client needs and fluent professional communication. An efficient response mechanism ensures seamless information exchange.

We adhere to a rigorous service process system, using market insights and forward-looking philosophies to deliver transparent and exceptional service experiences, demonstrating our commitment to professional service value.

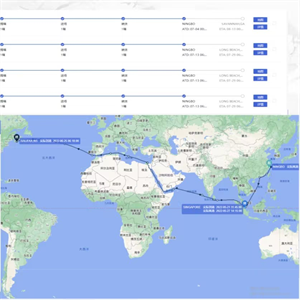

Strategic partnerships with over fifty global freight forwarders ensure expedient delivery and compliance with customs clearance requirements. We offer zero-profit margin on freight charges to optimize customers' procurement costs.

Cutting-edge technology and over fifteen years of industry experience enable rapid delivery and successful project implementation from planning to execution, positioning us at the forefront of the glass products industry.

In today's competitive market, every decision matters. Partner with us to access a reliable, high-quality supplier channel. We offer professional support to help you make informed decisions, seize opportunities, and grow your business. Contact us anytime for inquiries or collaboration.

Provide Delivery Date

We provide a confirmed delivery date to ensure clear production scheduling and transparent communication.

First Article Inspection

A first article inspection is conducted to verify that initial samples meet all technical and quality requirements before mass production.

In-Process Quality Control (IPQC)

Our quality team performs continuous in-process inspections to maintain consistent standards throughout production.

Production Process Demonstration

We share detailed production process updates and demonstrations, offering full visibility into every manufacturing step.

Final Quality Control (FQC)

Each batch undergoes a thorough final inspection to guarantee product reliability and performance before shipment.

Packing List (PL) and Freight

A complete packing list and freight arrangement are prepared to ensure safe, accurate, and timely delivery.

Warehouse Receipt Photos

Photos of the packaged goods in our warehouse are provided for confirmation before shipment.

Transportation Plan

We create a detailed transportation plan outlining the best shipping method, schedule, and route.

Customs Clearance Documents

All necessary customs documents are prepared and verified to ensure smooth and efficient clearance.

Transportation Route Map

A visual route map is shared to keep you informed about the shipment’s journey and estimated arrival.

Track the Receipt of Goods

We continuously track your shipment and confirm delivery to ensure everything arrives safely and on time.

After-sales Service

Our after-sales team remains available to provide support, handle feedback, and ensure complete customer satisfaction.

Easter Glass has been awarded the ISO9001 international quality management system certification. Easter Glass has always adhered to the principle of seeking survival through quality and development through reputation.

We have obtained the RoHS Compliance Test Report for our glass products, confirming they meet the RoHS Directive standards for environmental safety and human health protection.