Client Challenge

1. Require 7J impact testing

2. Bottom must be flat and sealed

3. Must be explosion-proof and safe

4. Urgent project — sample required within 4 weeks

Our solution

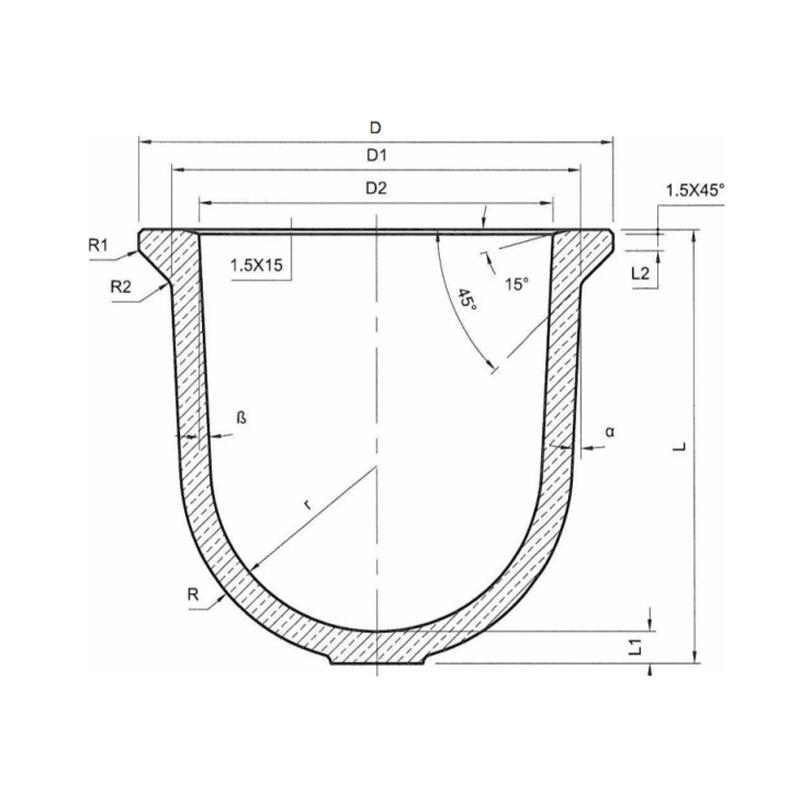

1. The client’s original drawing specified 6mm, but we increased it to 9mm without changing the usage scenario;

2. Normally, our explosion-proof lamp covers are chemically toughened, but to meet the client’s requirement of 7J impact testing, we upgraded to physically toughened glass;

3. While emphasizing physical toughening, we ensured the glass also meets European and American standards.

Final Result

1. Agreed with the client to increase the thickness to 9mm without affecting their usage.

2. To achieve physical toughening, we designed a specialized tempering furnace, and the tempered glass met the expected physical performance and fragmentation standards (>40 fragments per 50×50mm).

3. Top impact tests successfully achieved >7J.

4. Achieved 85% transparency and light transmittance.

5. From drawing to sample in just 28 days.

◆ 28 days from drawing to sample ◆ >7J top impact achieved >7J ◆ >40 fragments per 50×50mm