Client Challenge

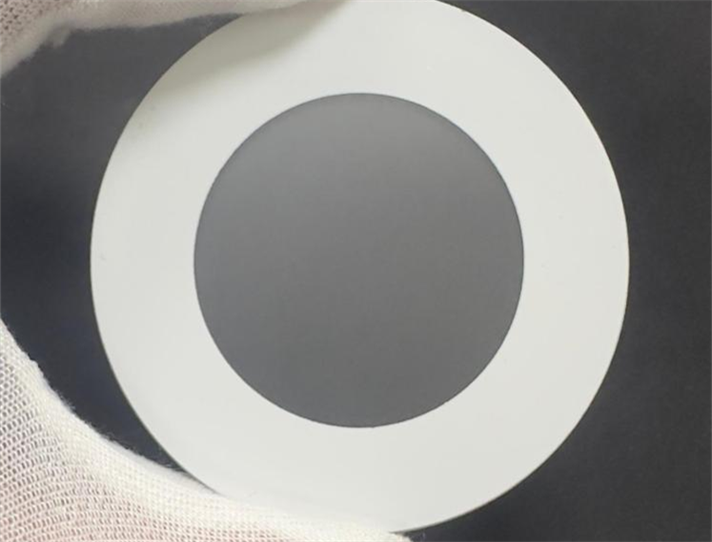

1, Only an AG glass sample provided, with no haze or roughness data.

2, Visual effect judged by eye only, lacking measurable criteria.

3, Without standards, mass production risked instability and inconsistency.

Our solution

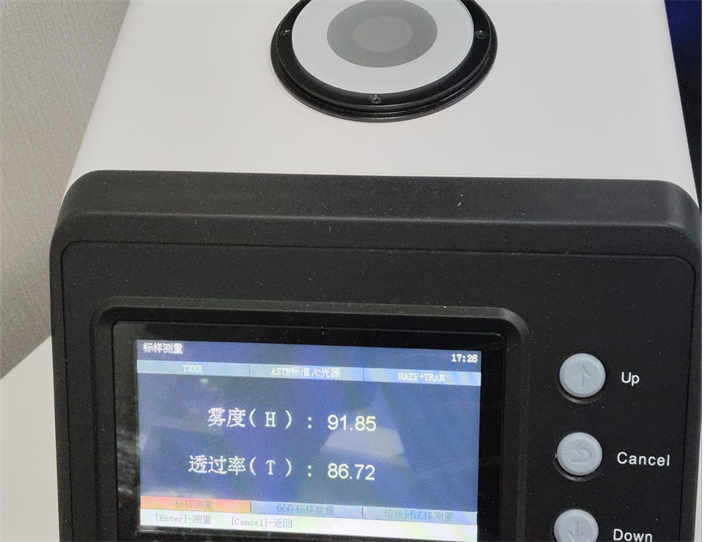

1, Data visualization – Used haze meter & roughness tester to quantify visual effects.

2, Material standardization – Shared measured data with suppliers to align raw materials.

3, Full inspection – Implemented 100% QC during mass production to match benchmark data.

Final Rezult

1, Full inspection – Implemented 100% QC during mass production to match benchmark data.

2, Engineering & QC teams built a testing system and data model, cutting development time by 36%.

3, Final lighting effect fully met the client’s expectations, Client gained reliable data-based standards, reduced project risks, and strengthened long-term trust with Easter Glass.

◆ 91.7(±0.5) Haze Value ◆ 86.4% Transmittance ◆ 100% Pass Rate