Client Challenge

For indoor pendant chandeliers, the larger the glass globe, the larger the aperture required, which in turn demands bigger hardware for installation.

1. Oversized metal fittings compromise the premium look of the entire luminaire.

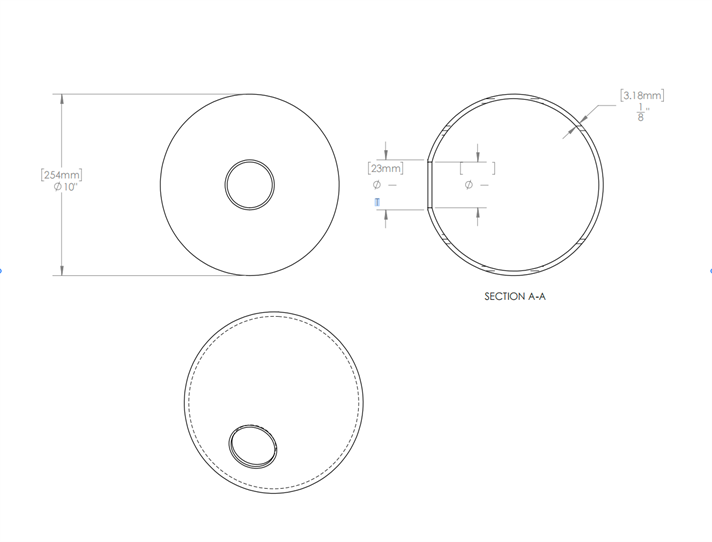

2. To achieve a truly high-end design, the aperture needed to be kept within 23mm while still allowing installation with a G9 nut.

3. The project was urgent, with a strict 4-week timeline for sample delivery.

Our solution

1. Our team had prior experience producing glass globes from 3" to 9" with 23 mm openings that could accommodate G9 threading.

2. Building on this, the production team initiated a 10" trial run, developing test molds and training craftsmen to adapt their techniques. The trial succeeded.

3. We then advanced to an 11" mold and sample development. The first and second attempts failed, but after thorough review and adjustments, the third attempt succeeded, leading to stable mass production.

Final Result

1. We successfully achieved a technical breakthrough: producing an 11" opal blown glass globe with a 0.9" small aperture that could securely hold a G9 nut.

2. Our production team expanded technical limits, moving from a maximum diameter of 10" to 11".

3. Despite the urgent timeline, samples were delivered within 4 weeks, exactly as requested.

4. The samples met expectations, enabling the client to gain control of the project and successfully close the deal with their end customer.

5. The smooth transition from sample to mass production allowed the project to scale seamlessly, directly supporting the client’s business growth and sales performance.

◆ 4 weeks From Drawing to Sample ◆ <9’mm hole Achieved on Ø11”Glass Globe ◆ Performance Improvement Achieved additional revenue of $100,000