Client Challenge

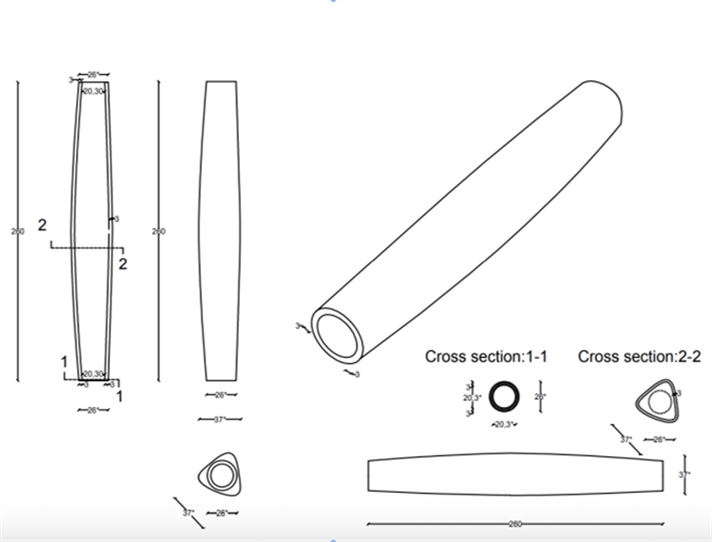

1, Zero tolerance for misalignment – installation had to be seamless, no deviation or visible gap was acceptable.

2, Complex shape with uniform thickness – the triangular design required precise geometry; uneven walls would prevent assembly and delay the project.

3, Accurate inner diameter & length with color finish – dimensions had to be exact; too short would enlarge the aperture, and a precise spray-color finish was mandatory.

Our solution

1, Custom mold precision – For long, slim, shaped glass tubes, manual forming was not reliable; custom molds ensured accuracy.

2, Adopted press-blow process – This technique delivered consistent dimensions and uniform wall thickness, leading to successful sample development.

3, Simulated installation & custom gauge – Testing tools replicated real assembly conditions, ensuring every tube met the client’s design requirements.

Final Rezult

1, Every tube achieved ±0.2 mm tolerance, with flawless spray-color finish and stable quality.

2, Engineering and QC teams collaborated seamlessly, finishing development 2 weeks ahead of schedule.

3, The client’s project was installed on time with zero fitting errors, strengthening confidence for future collaboration.

◆ 14 days faster Lead Time ◆ <±0.2 mm Dimensional Precision ◆ 100% Installation Success Rate