- Overview

- Recommended Products

-

Mold

-

Raw Material melting

-

Hand-Blown

-

Annealing

-

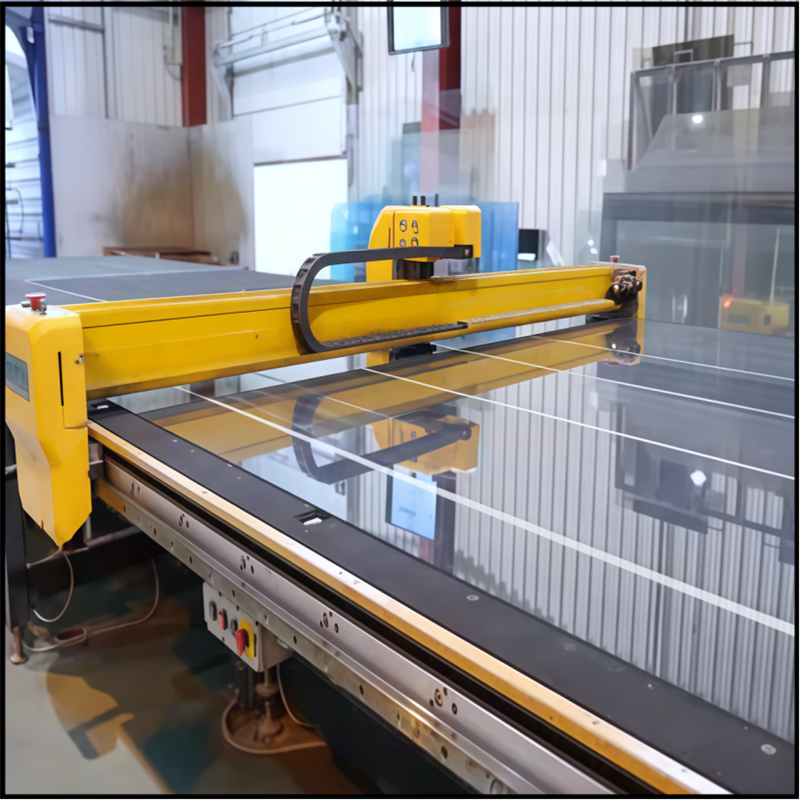

Hole Drilling

-

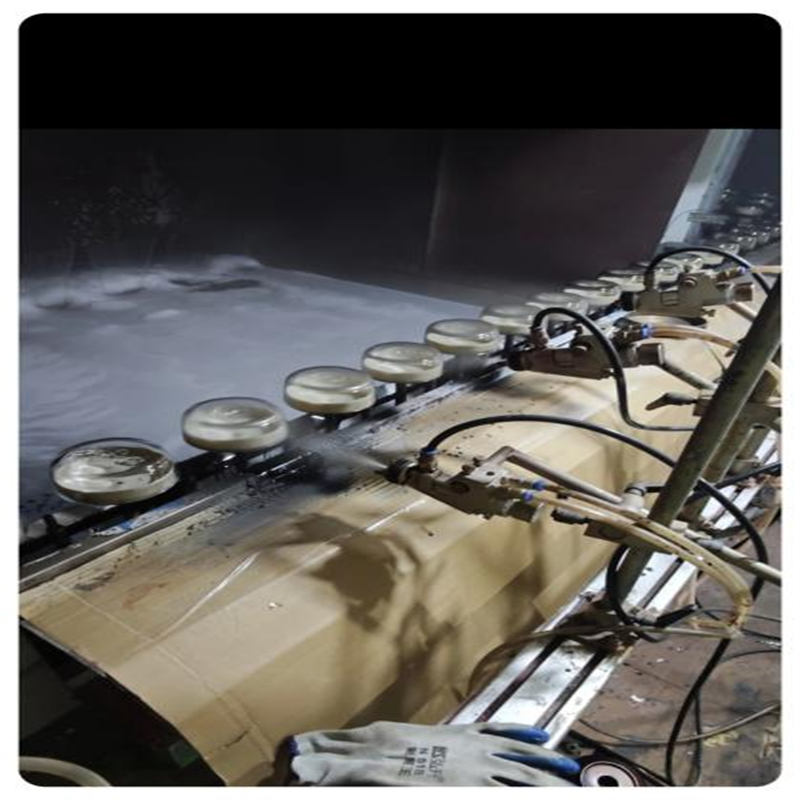

Color Spraying

-

Cleaning

-

Inspection

-

Packing

-

Delivery

The production of Hand-Blown Fused Glass begins with mold preparation, followed by melting high-quality raw materials in the furnace. Skilled artisans then blow and shape the molten glass by hand. After forming, each piece undergoes annealing to relieve internal stress, ensuring durability. The glass is then cut and drilled according to customer requirements. Additional treatments such as color spraying, acid etching, or engraving are available upon request. We inspect each piece under light to ensure clarity and quality, and test fittings with customer-provided accessories. Finally, products are packed securely in export-safe cartons with pallets or wooden crates for safe shipment worldwide.

Reference for packaging pictures

To ensure glass products remain intact during transportation, we offer diverse and professional packaging solutions. The standard packaging features a double-protection structure of cross-grid dividers and bubble wrap — the grid stabilizes items while the bubbles cushion against impacts and vibrations. For higher protection needs, we support custom independent small boxes tailored to your product's unique shape for exclusive safeguarding. All outer cartons are high-strength boxes printed with safety exit markings for easy identification and handling. Additionally, based on cargo weight and shipping requirements, we provide palletizing or wooden crate packaging, reinforcing bases and frames to fully secure goods for worry-free delivery.