- Overview

- Recommended Products

-

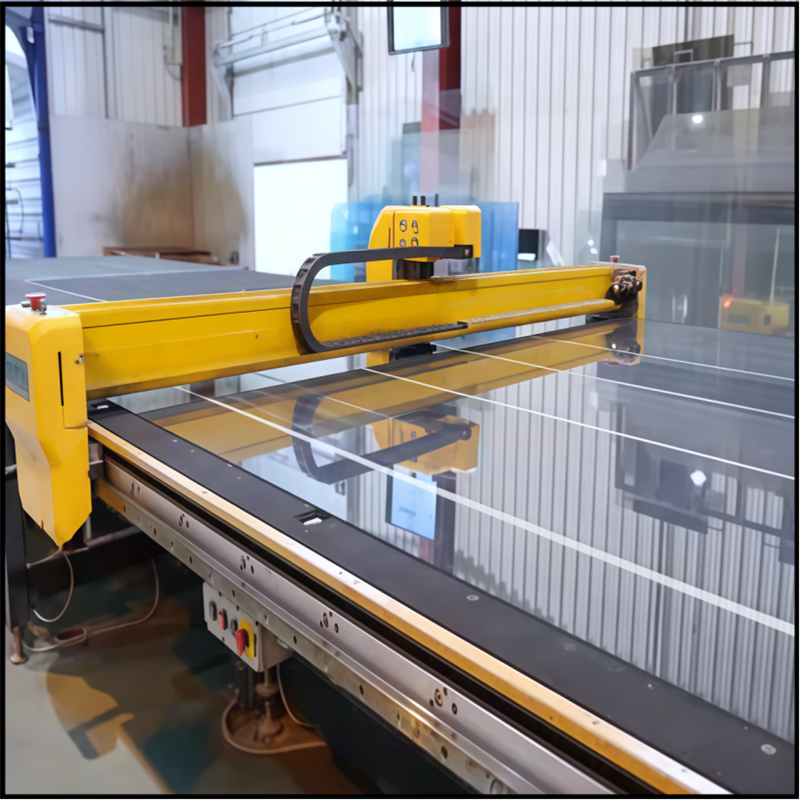

Raw materials

-

Fire softening

-

Draw benching

-

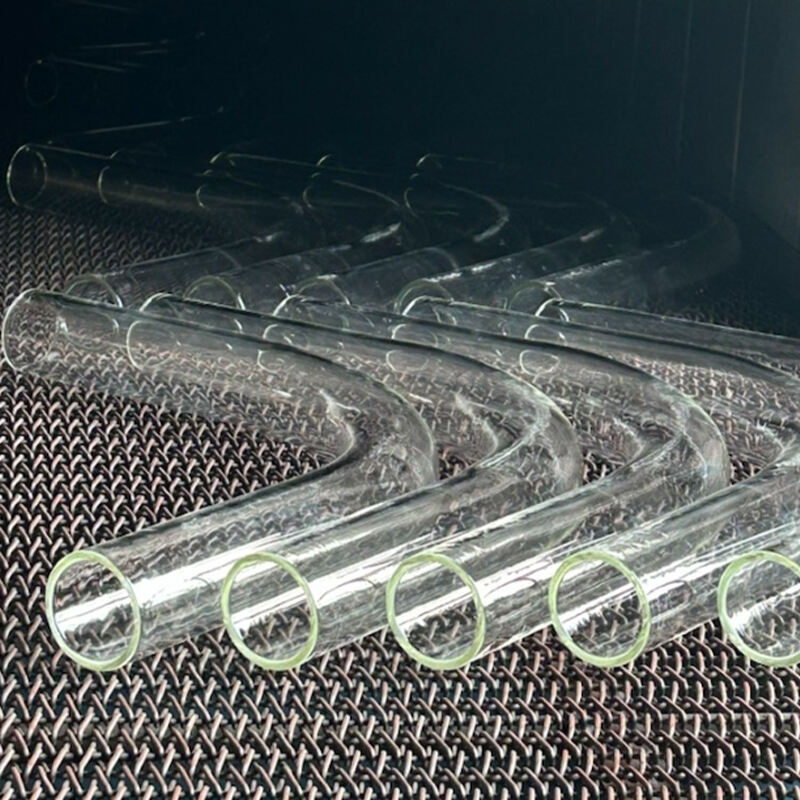

Preheating

-

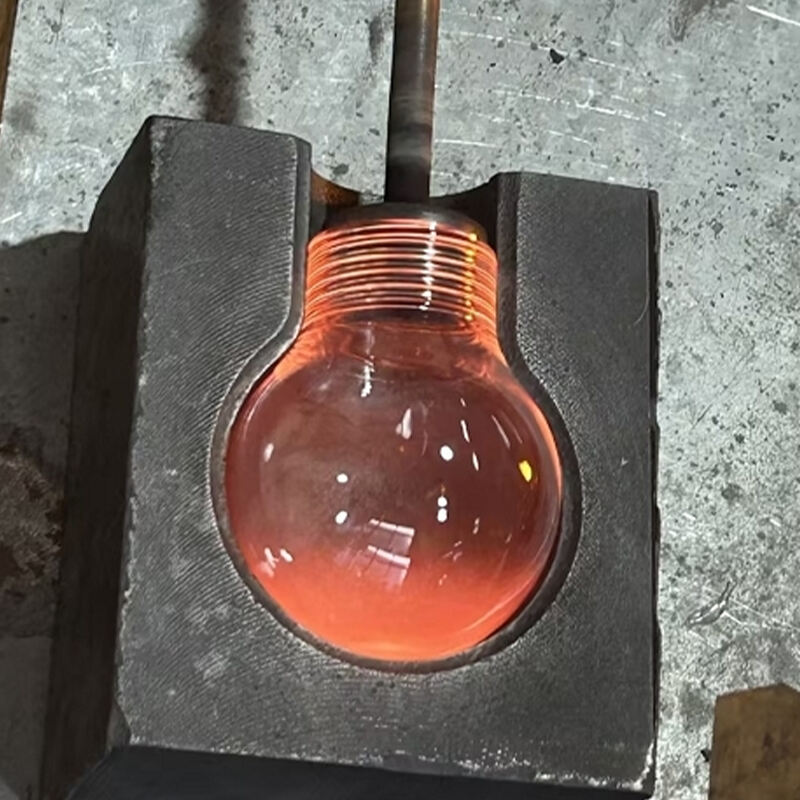

Mold blowing

-

Fire polishing

-

Annealing

-

Inspection

-

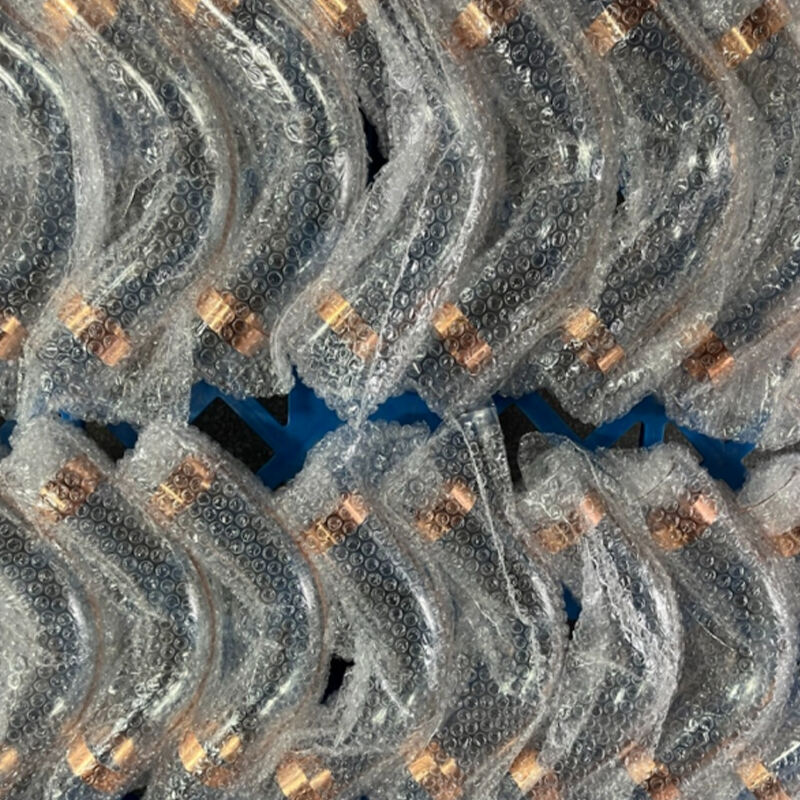

Packing

-

Delivery

-

-

-

-

The high borosilicate manual blowing process with glass tubes as raw materials first heats the glass tube evenly in a high-temperature flame until it softens. When it turns into a transparent red-hot state, craftsmen quickly seal one end and use a special blowing pipe to inflate and shape it. Meanwhile, they control the extension and curvature of the glass by flexibly rotating and slightly pressing. After shaping, it is rapidly sent to an annealing furnace for slow cooling to eliminate internal stress. Finally, through fine cutting and polishing, unique high borosilicate glass products are completed.

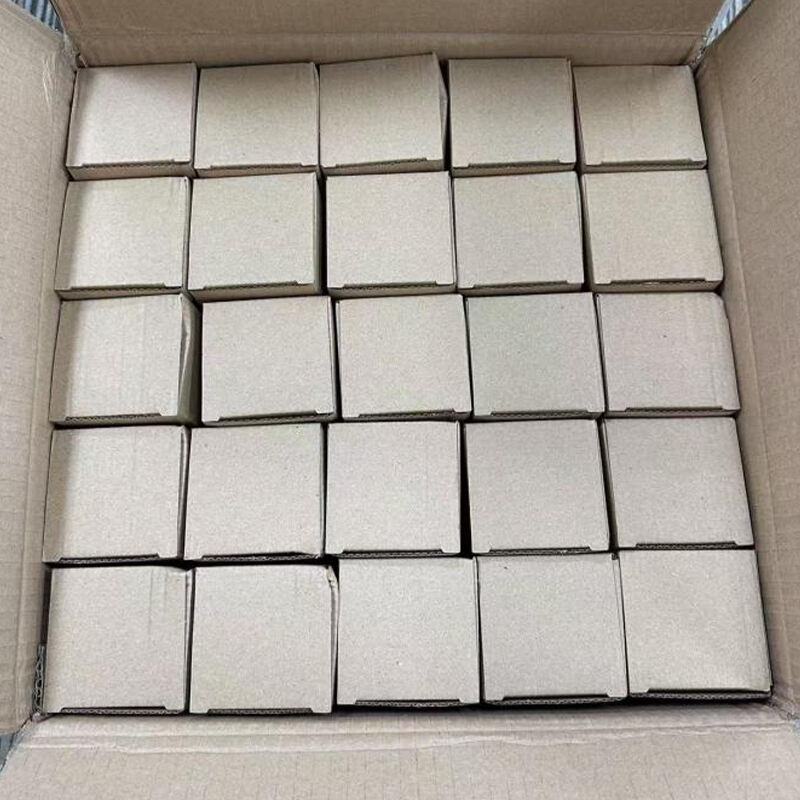

Reference for packaging pictures

To ensure glass products remain intact during transportation, we offer diverse and professional packaging solutions. The standard packaging features a double-protection structure of cross-grid dividers and bubble wrap — the grid stabilizes items while the bubbles cushion against impacts and vibrations. For higher protection needs, we support custom independent small boxes tailored to your product's unique shape for exclusive safeguarding. All outer cartons are high-strength boxes printed with safety exit markings for easy identification and handling. Additionally, based on cargo weight and shipping requirements, we provide palletizing or wooden crate packaging, reinforcing bases and frames to fully secure goods for worry-free delivery.