- Overview

- Recommended Products

-

Prepare Molds

-

Pressed with Molds

-

Annealing

-

Grind Edge

-

Dimensinos Inspection

-

Final Quality Check

-

Packing

-

Delivery

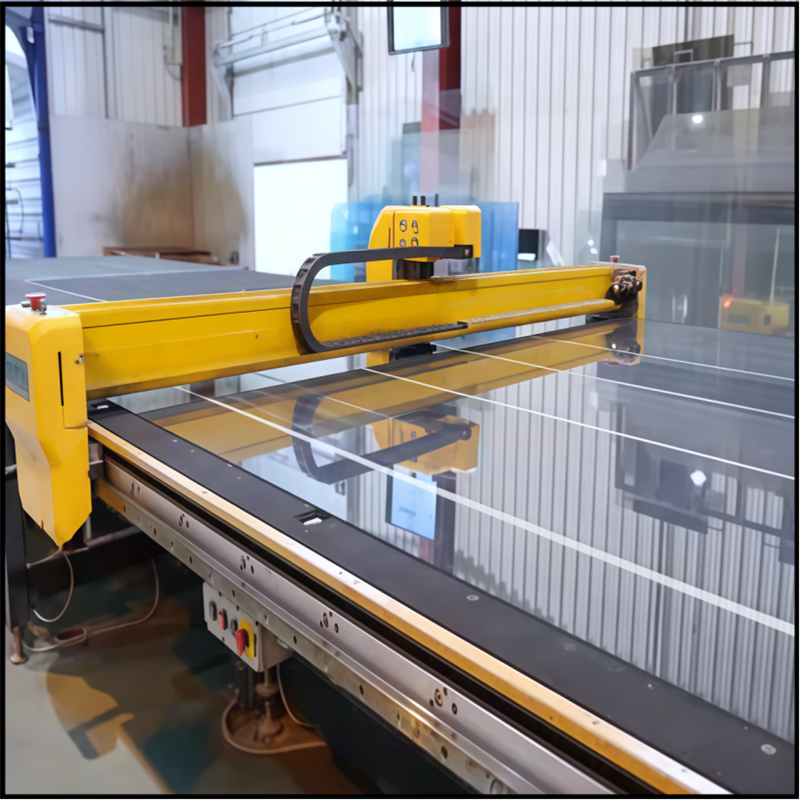

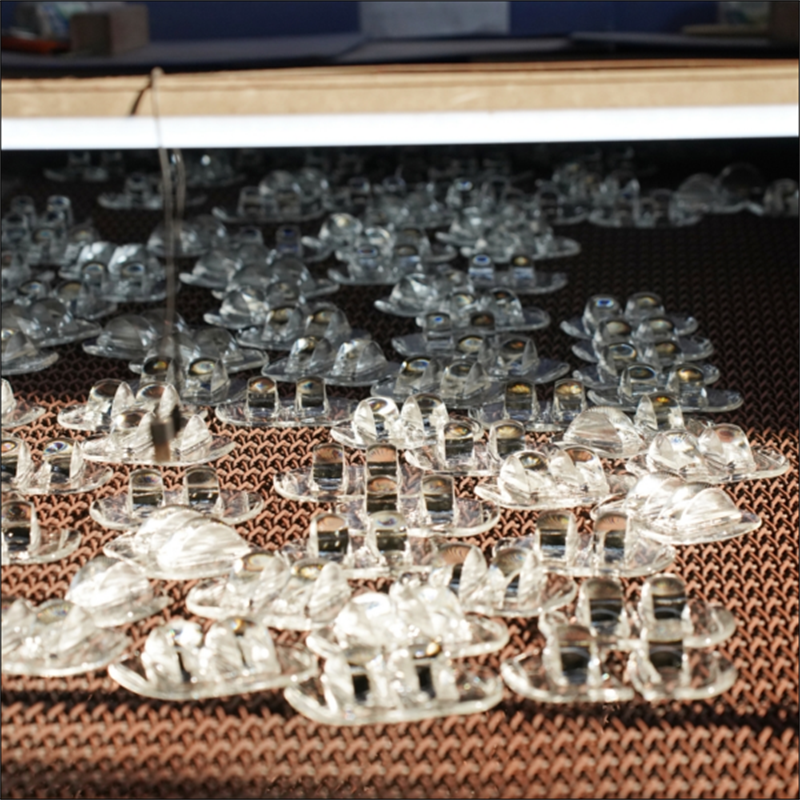

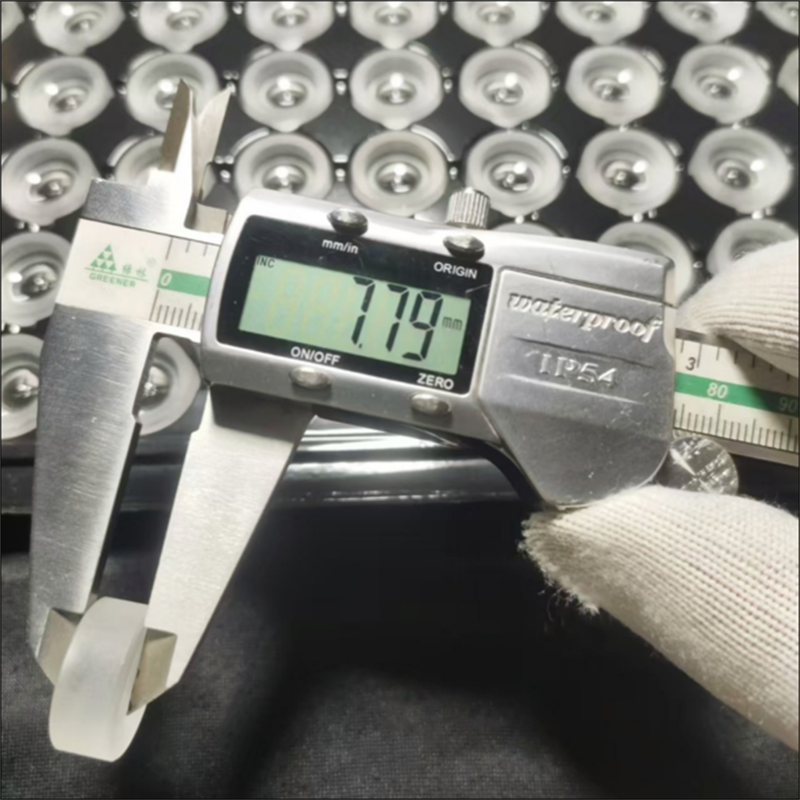

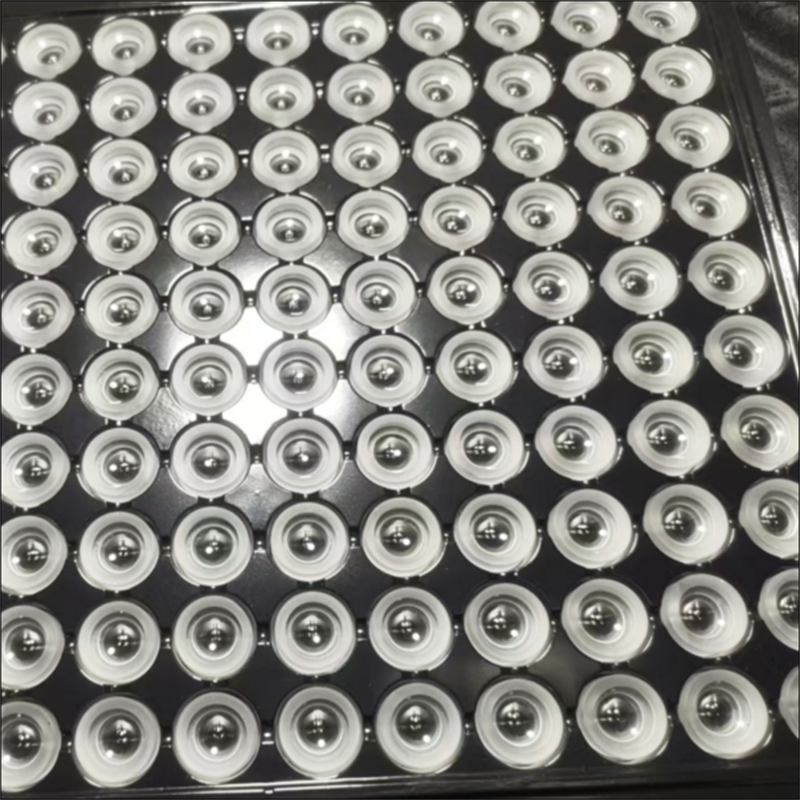

The materials for optical glass usually include BK7, B270 and high borosilicate rod materials. In the production process of optical glass, first, the raw materials need to be initially cut according to the size of the product. Then, the cut raw materials are heated to a high temperature to melt them into a semi - liquid state. Subsequently, they are injected into the mold for pressing at the fastest speed. The pressed semi - finished products are put into a high - temperature annealing furnace for annealing treatment. After annealing, subsequent processes such as grinding, polishing and cleaning are carried out on the products. Finally, the processed products are subjected to dimensional inspection and other experiments. Through the above series of processes, it is ensured that the size and optical performance of the products can meet the requirements of customers.

Reference for packaging pictures

To ensure the safety of products during transportation, we typically use a packaging method that combines crisscross dividers with brown five-layer corrugated cartons. For products with special requirements for surface smoothness, we will select more suitable packaging methods based on specific circumstances, such as blister packaging or placing individual products in white inner boxes. In addition, we can also provide customized packaging services according to your special needs. Before arranging the transportation of goods, we will load all outer cartons into pallets, wooden cases, or wooden frames to reduce the risk of collision or falling that may occur during long-distance transportation.