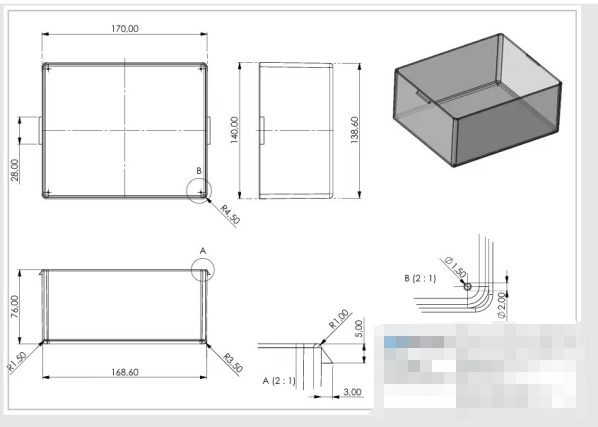

A client from the United States sought to transition from an acrylic material to glass for their UV-curing box used in product processing.

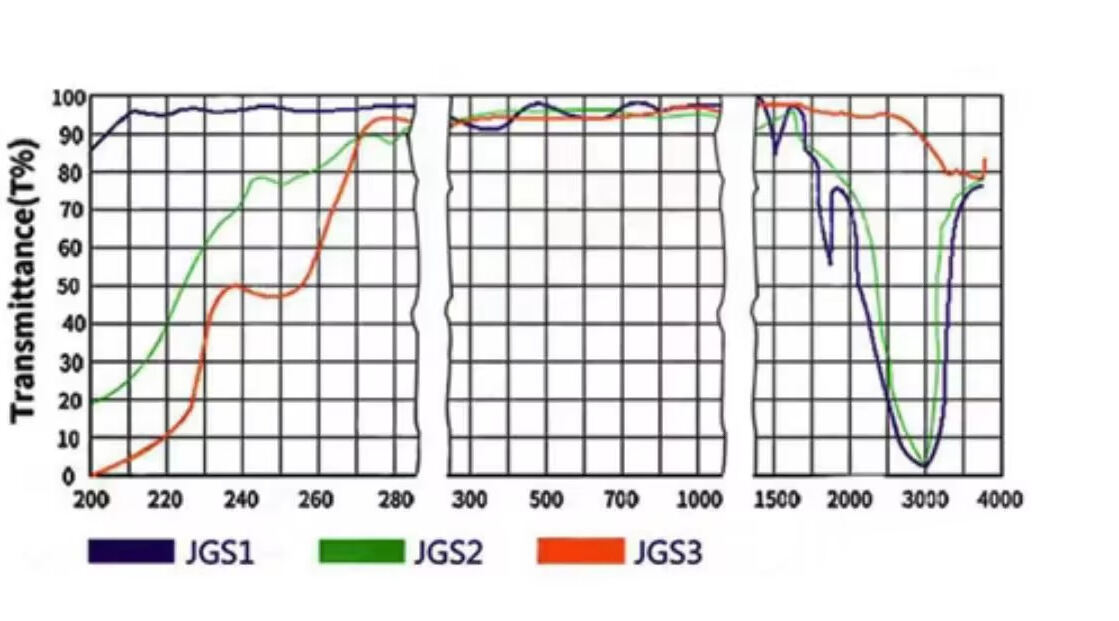

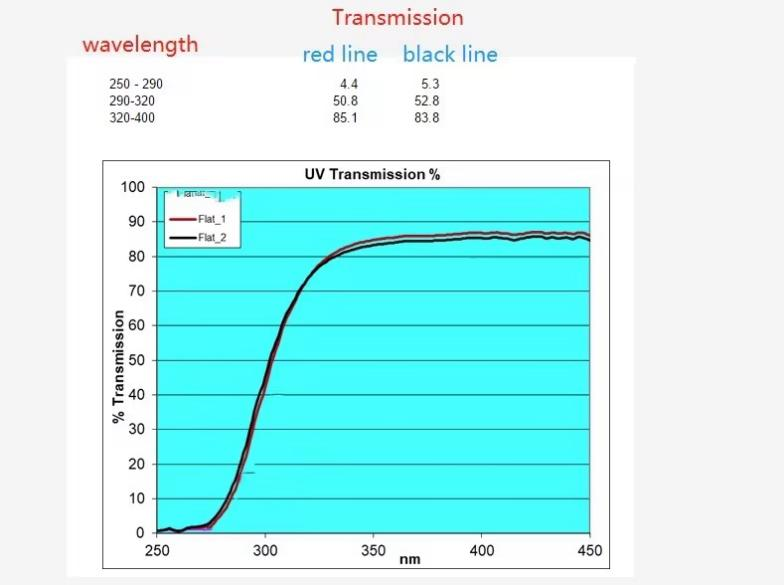

Through detailed discussions with the Easter Glass team, we promptly devised a comprehensive plan. Leveraging our specialized knowledge of glass materials, we presented two viable options: high borosilicate glass is suitable if the ultraviolet wavelength exceeds 256 nanometers; quartz material is required for wavelengths between 180 and 256 nanometers, though it incurs costs approximately four times higher than high borosilicate glass. Given that the client's light source emits UV radiation at around 200 nanometers, quartz was initially deemed necessary to meet design and functional requirements.

We also proposed an optimized alternative: replacing the light source could achieve the desired outcome without necessitating the use of quartz. Ultimately, the client opted for the high borosilicate glass solution, which not only fulfilled the original specifications but also resulted in significant cost savings.