In the field of glass products, the realization of orange-peel-like textures glass lenses has always been a complicated issue, which has caused headaches for clients. Most customers are often daunted by orange peel glass, which is mainly due to several major problems. First, it is difficult to achieve the expected diffusion effect of light output and cannot meet the lighting needs; second, the inspection is quite difficult. It is hard to accurately judge the product quality by simply relying on simply visual inspection and tactile inspection, and it is easy to have deviations; third, the lack of unified and clear standards makes production and acceptance like crossing a river by feeling the stones, full of uncertainty.

Easter Glass also encountered these difficult problems during consistent R&D and production process. However, we did not back down, but found a set of effective solutions through continuous practical exploration.

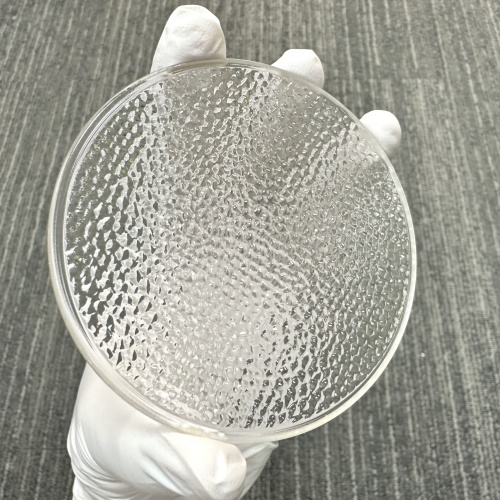

The first step is to accurately reproduce the orange peel texture on the mold, which is the first key step in creating high-quality orange peel glass. Usually, we rely on the exquisite knocking skills of the craftsmen, with rich experience and hands-on skills, to knock out delicate and realistic orange peel texture on the mold. At the same time, some products will also use the pickling process to achieve the ideal orange peel effect. As shown in the mold shown in the attached figure, the orange peel texture on its surface is clearly discernible, laying a solid foundation for subsequent production.

After completing the mold making, we produced samples through the pressing process. The appearance of the product is shown in the attached figure, and it has the texture of orange peel glass.

In order to overcome the problem of light diffusion, we conducted many repeated experiments. Finally, we found the best way to achieve the diffusion effect: under the premise that the mold state is fully up to standard, by flexibly adjusting the mold temperature and production speed, the glass can be evenly stressed and fully formed during the pressing process. And the most convenient way to test this effect is to use a laser pen. As shown in the attached figure, we magnified a beam of light by more than 100,000 times, and by comparing the scattering state of the laser on different samples, we can intuitively judge whether the light diffusion effect is up to standard.

With such a simple and efficient inspection method, we not only ensure the stability and consistency of the quality of each batch of orange peel glass, but also help us standardize and finalize the production process, greatly improving production efficiency and product quality. Today, Easter Glass has successfully broken through the bottleneck of orange peel glass production with this solution, presenting high-quality and high-standard products to customers, and winning market favor.